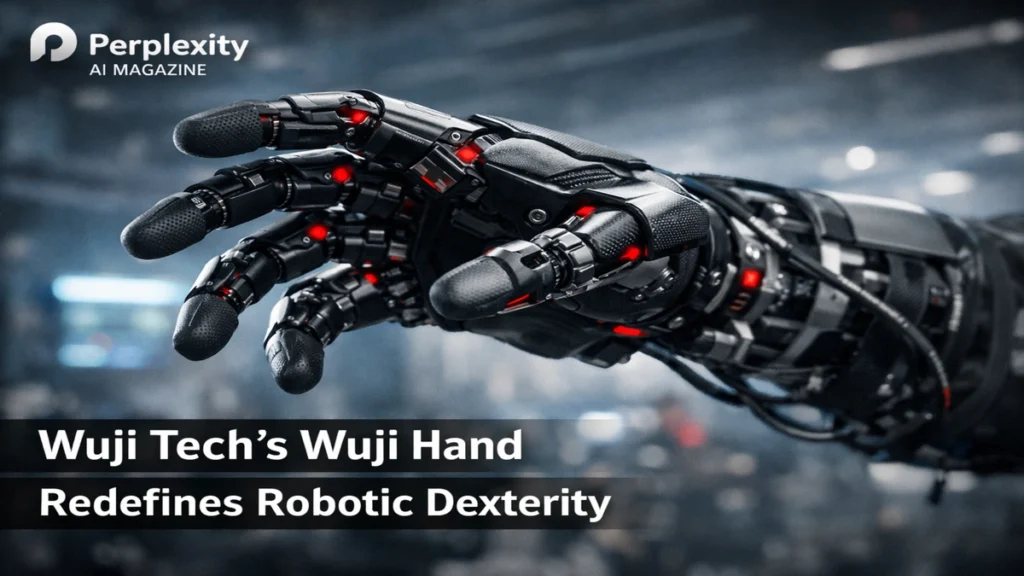

I have watched robotic hands struggle for years to match what a child can do without thinking: pick up a coin, hold scissors, twist a lid. For decades, dexterity remained robotics’ quiet bottleneck. The Wuji Hand, introduced by Chinese robotics company Wuji Tech in September 2025, addresses that constraint directly. It is a human-sized, five-finger robotic hand with 20 active degrees of freedom, each joint independently controlled through embedded direct-drive micro-actuators. Weighing roughly 0.9 kilograms assembled and measuring about 20 centimeters in length, it delivers approximately 15 newtons of fingertip force and can maintain a static full-hand grasp of around 10 kilograms, with some demonstrations pushing higher under controlled conditions.

The promise is not simply stronger grip. It is repeatable, uncoupled motion at high control frequencies near 1 kilohertz, enabling precise manipulation without tendon slack or calibration drift. Wuji positions the hand for humanoid robots, research laboratories and advanced prosthetic experimentation, with pricing tiers reported between about $5,500 and $16,000 depending on configuration. In a robotics industry often dominated by prototypes, the Wuji Hand arrives as a deployable tool, not just a research curiosity.

A Mechanical Architecture Built for Precision

The Wuji Hand features 20 active degrees of freedom, distributed evenly across five fingers. Each finger includes four independently controlled joints. Instead of routing cables or tendons through the palm to external motors, Wuji embeds micro-actuators directly into the fingers and palm structure. This design enables true joint-level independence, meaning that flexion in one joint does not mechanically interfere with neighboring joints.

The skeleton of the hand weighs under 600 grams, with the full assembly near 0.9 kilograms. Despite its compact mass, it is engineered for durability. Wuji reports more than 300,000 grasp cycles and shock resistance capable of withstanding drops from roughly 80 centimeters. Those metrics matter in applied robotics, where laboratory performance often falters under repeated stress. By integrating actuators at the joint level, the system reduces backlash and compliance common in remote motor systems. The result is motion that is both crisp and measurable, an important quality for machine learning models that rely on precise actuation feedback.

Read: KB5071959 Explained: Windows 10 ESU Fix

Direct Drive Versus Tendon Systems

Robotic hand design often comes down to a central engineering trade-off: tendon-driven systems versus direct-drive actuation. Tendon systems place motors in a forearm or external housing, pulling cables to flex the fingers. They can approximate biological muscle behavior, but introduce slack, wear and calibration complexity. Over time, tendons stretch, friction increases and control fidelity suffers. – wuji tech.

The Wuji Hand adopts a direct-drive architecture. Each joint contains its own rotary micro-actuator using field-oriented control. Because motion originates directly at the joint, lag is minimized and torque delivery is immediate. Feedback operates at high frequency, near 1 kilohertz, enabling fine control loops across all 20 axes. Engineers say this reduces the simulation-to-real gap, the persistent mismatch between robotic behavior in digital environments and physical execution in the real world.

Below is a structured comparison of the two approaches.

| Feature | Wuji Hand | Typical Tendon-Driven Hand |

|---|---|---|

| Degrees of Freedom | 20 independent | 10 to 16, often coupled |

| Actuation | Embedded direct-drive | Remote motors with tendons |

| Control Frequency | ~1 kHz feedback | Lower, tendon latency |

| Calibration | Minimal drift | Requires periodic tuning |

| Dexterity | High, uncoupled motion | Limited by compliance |

The distinction is not academic. It affects repeatability, long-term durability and the ability to execute delicate tasks without mechanical interference.

Strength and Load Capacity in Context

The Wuji Hand is engineered for balance between finesse and force. Each fingertip can exert about 15 newtons of force, roughly 3.3 pounds. While that may appear modest compared with industrial grippers designed for heavy manufacturing, the combined static grasp of the full hand reaches about 10 kilograms. Some demonstrations suggest dynamic handling of heavier loads under optimal conditions. – wuji tech.

More important than raw strength is the distribution of torque across independently controlled joints. The hand can execute a dual-finger pinch capable of supporting approximately 5 kilograms. That opens the door to tasks such as tool manipulation, container lifting and component assembly requiring controlled opposition between digits.

Durability metrics also matter. With more than 300,000 reported grasp cycles and resistance to moderate drop impacts, the hand is positioned for research environments where repetitive motion is constant. In robotics, failure often occurs at the end effector. By reinforcing structural elements and embedding micro-actuators securely within the phalanges and palm, Wuji aims to reduce wear points common in tendon systems.

Read: ERR_CONNECTION_TIMED_OUT Error Explained and Fixed

The Thumb as a Design Statement

Human dexterity is defined largely by the thumb. Wuji gives its thumb four degrees of freedom, matching the other fingers. The carpometacarpal joint incorporates three axes of rotation but functions effectively as 2.5 degrees of freedom due to non-orthogonal axes designed for compact opposition.

An embedded micro-actuator in the proximal phalanx drives distal motion through a gearbox that adjusts torque and rotation direction. The thumb is mounted in reverse orientation relative to the other fingers to improve opposition mechanics. That configuration supports precision tasks such as scissor use or controlled pinching without tendon coupling.

In robotics, the thumb often becomes the limiting factor in manipulation tasks. By engineering its opposition geometry carefully, Wuji enhances grasp diversity. The result is not simply biomimicry but optimized mechanical alignment for robotic control algorithms. – wuji tech.

Developer Tools and Software Integration

Hardware innovation means little without integration pathways. Wuji provides a developer-ready SDK built on a C++ core with Python bindings. The software supports joint position and velocity control, calibration routines and communication setup across interfaces including USB, RS485 and EtherCAT.

Feedback rates approach 1 kilohertz, enabling high-frequency sensor data for closed-loop control. Developers can initialize the system through a simple Python interface, connect via standard serial ports and command all 20 joints simultaneously. This accessibility lowers the barrier for robotics laboratories experimenting with reinforcement learning, teleoperation or humanoid integration. – wuji tech.

Unlike proprietary systems that lock developers into closed ecosystems, Wuji’s open software structure allows rapid prototyping. Researchers can embed the hand into existing humanoid frames or mount it on test rigs for manipulation studies. That flexibility is central to its positioning in academic and industrial research communities.

Read: Ark Augmented Reality Explained: Adaptive AR with AI

Pricing and Market Position

Robotic hands with comparable articulation historically cost far more than mid-range industrial components. High-end research manipulators often reach six-figure price points. Wuji’s reported pricing range, roughly $5,500 for lower tiers and up to $16,000 for full configurations, places it within reach of smaller labs and startups.

Below is a structured overview of positioning.

| Attribute | Wuji Hand |

|---|---|

| Launch Date | September 2025 |

| Target Users | Humanoid robots, research labs, prosthetics |

| Weight | ~0.9 kg assembled |

| Active DOF | 20 |

| Price Range | ~$5,500 to ~$16,000 |

| Control Interfaces | USB, RS485, EtherCAT |

Post-launch buzz into 2026 includes backorder availability and analysis from robotics observers praising the robustness of the direct-drive architecture. Wuji appears to be pursuing a strategy of practical accessibility rather than exclusivity.

Performance Versus Tesla Optimus

Comparisons with Tesla’s Optimus hand are frequent. Optimus relies on tendon-driven mechanisms with motors positioned in the forearm, offering between 10 and 16 degrees of freedom depending on iteration. Tendon systems can achieve biomimetic aesthetics, but often introduce lag and calibration challenges. – wuji tech.

Wuji’s 20 fully actuated joints exceed that articulation count. Independent joint control improves fine motor repeatability, particularly for tasks requiring synchronized multi-joint motion without coupling. While Optimus prioritizes humanlike form, Wuji emphasizes control precision and robustness.

The distinction highlights two philosophies. One pursues biomimicry. The other prioritizes controllable mechanics. In applied robotics, repeatability and calibration stability often outweigh aesthetic resemblance.

Expert Perspectives

Robotics engineers observing the design have pointed to the high-frequency feedback loop as a key differentiator. One industry researcher described the architecture as “a meaningful step toward closing the sim-to-real gap in manipulation systems,” noting that direct-drive reduces variables that complicate learning models.

Another robotics consultant emphasized durability, stating that “embedding micro-actuators within the joint structure simplifies maintenance and reduces points of failure compared to tendon assemblies.” Durability metrics such as 300,000 grasp cycles signal engineering confidence beyond laboratory prototypes. – wuji tech.

A third academic specializing in humanoid manipulation observed that “the thumb design alone makes this a platform worth studying,” citing its opposition geometry and torque routing as critical to grasp diversity.

These assessments underline that the Wuji Hand’s significance lies not only in specifications but in architectural coherence.

Practical Applications Across Fields

The Wuji Hand’s capabilities position it across multiple domains. In humanoid robotics, it offers an end effector capable of interacting with tools designed for human hands. In research laboratories, it provides a platform for studying dexterous manipulation, tactile integration and adaptive control algorithms.

In prosthetics research, its human scale and independent actuation suggest potential for advanced prosthetic prototypes, particularly when paired with sensory feedback systems. While commercial prosthetic integration would require additional refinement, the mechanical foundation aligns with emerging trends in neuro-robotic interfacing.

Manufacturing and logistics may also benefit. As automation expands into tasks requiring fine handling rather than bulk lifting, dexterous hands become increasingly valuable. Precision assembly, quality inspection and packaging tasks demand nuanced motion control rather than brute force. – wuji tech.

Takeaways

• Wuji Hand features 20 fully independent degrees of freedom using embedded direct-drive micro-actuators.

• High-frequency feedback near 1 kilohertz enhances precision and repeatability.

• Static grasp capacity reaches about 10 kilograms with 15 newtons of fingertip force.

• Durable design supports over 300,000 grasp cycles and moderate drop resistance.

• Developer-friendly SDK and multiple communication interfaces ease integration.

• Competitive pricing broadens accessibility compared with traditional research hands.

• Direct-drive architecture reduces tendon slack and calibration complexity.

Conclusion

I see the Wuji Hand as evidence that robotic dexterity is moving from spectacle to infrastructure. Its value lies not in promotional demonstrations but in structural choices that prioritize controllability, durability and accessibility. By embedding 20 micro-actuators directly within the hand, Wuji rethinks a decades-old mechanical paradigm and challenges tendon-based dominance in humanoid robotics.

Whether deployed in research labs, integrated into humanoid frames or explored in prosthetic prototypes, the Wuji Hand signals a transition toward reliable manipulation platforms. The future of robotics will not hinge solely on artificial intelligence models or vision systems. It will depend equally on the mechanical intelligence at the fingertips. Wuji’s contribution suggests that this frontier is finally catching up.

FAQs

What is the Wuji Hand?

The Wuji Hand is a five-finger robotic hand from Wuji Tech featuring 20 independently actuated degrees of freedom and direct-drive micro-actuators.

How much force can it exert?

Each fingertip produces about 15 newtons, and the full hand can maintain static grasps of roughly 10 kilograms.

How does it differ from tendon-driven hands?

It embeds motors directly in each joint, reducing slack, calibration issues and control lag associated with tendon systems.

Who is it designed for?

It targets humanoid robotics developers, research laboratories and advanced prosthetic research teams.

Is software support available?

Yes. Wuji provides a C++-based SDK with Python bindings and support for USB, RS485 and EtherCAT communication.