i remember when robots still felt like distant science fiction, boxed inside factory cages and programmed for a single task. Today, that distance has collapsed. In the past year alone, robotics has crossed a threshold, not with spectacle, but with steady, practical progress. Collaborative robots now lift heavier loads safely beside humans. Humanoid machines are moving from research labs into homes. Artificial intelligence has shifted robots from scripted automation toward learning systems that adapt in real environments. – robotics news.

Within the first hundred words, the story is clear. Robotics news in late 2025 and early 2026 is no longer about possibility but deployment. Manufacturers are responding to labor shortages with high-payload cobots that can be reconfigured in hours. Consumer robotics firms are betting that households are ready for humanoid assistants that fold laundry and water plants. Research institutions are blending vision, language, and touch into unified AI systems that allow robots to reason about the physical world.

What ties these developments together is convergence. Hardware has matured. Sensors are cheaper and more reliable. AI models trained on real-world data are finally robust enough to leave controlled environments. The result is a generation of robots designed not to replace humans outright, but to work alongside them, learning continuously and expanding what machines can do safely and autonomously.

This article traces that transformation across factories, farms, laboratories, and living rooms. It looks closely at the companies building these machines, the software that animates them, and the social questions that follow when robots stop being tools and start becoming collaborators.

Read: Artificial Intelligence Applications: Real-World Uses Across Industries

Collaborative Robots Move Into Heavy Industry

The newest chapter in collaborative robotics is defined by strength without intimidation. Omron has expanded its TM S Series with three high-payload cobots designed to operate in close proximity to human workers while handling tasks once reserved for industrial robots behind fences.

The TM30S can lift 30 kilograms, enough for palletizing and machine tending. The TM20S balances payload and reach for mid-scale operations. The TM6S focuses on precision work such as welding and inspection. All models now feature IP65 protection, allowing deployment in dusty or washdown environments that previously excluded cobots.

Software upgrades matter as much as hardware. Omron’s TMflow 2.22 introduces granular safety zoning, remote monitoring, and faster simulation for line changes. Landmark 2.0 vision reduces recalibration time when robots are moved, a critical advantage for manufacturers facing frequent product shifts. As one automation engineer at a European electronics plant noted, “the value isn’t just the payload. It’s how quickly we can redeploy when demand changes.” – robotics news.

Standard Bots has taken a parallel approach, integrating Cognibotics calibration technology into AI-driven cobot arms. The goal is consistency at scale, reducing setup friction so robots can be trained as flexibly as human workers.

Humanoids Step Out of the Lab

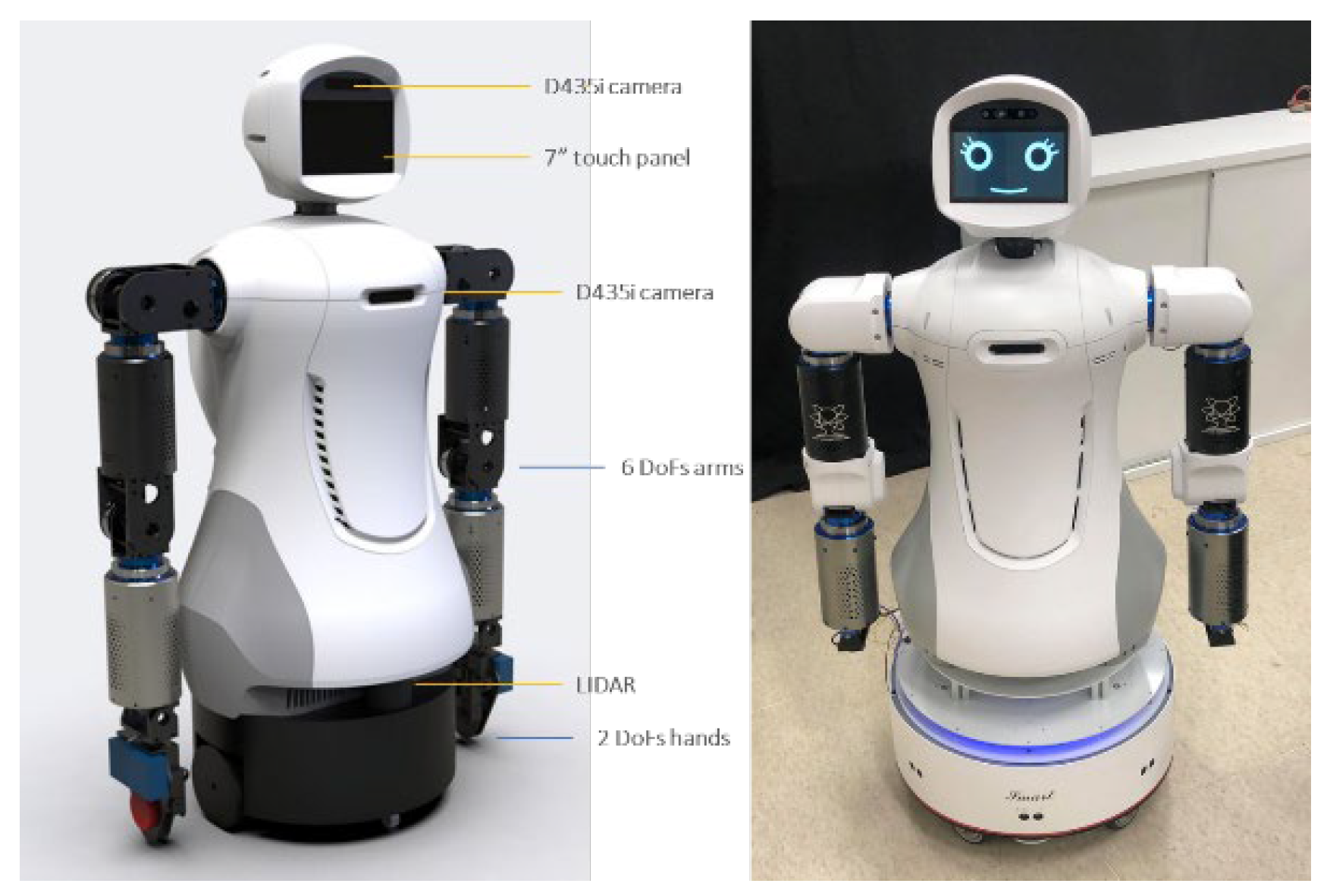

Humanoid robots once symbolized ambition more than utility. That balance is shifting. 1X Technologies has opened consumer preorders for its NEO humanoid, signaling confidence that home robotics is ready for a mainstream trial.

NEO is designed around domestic realities. It carries up to 55 pounds, lifts more than 150 pounds with two arms, and performs scheduled chores like tidying, laundry handling, and plant watering. Control is split between voice, mobile app, and an “Expert Mode” that allows remote human operators to teach new tasks, feeding data back into its Redwood AI system.

Pricing reflects an attempt to normalize ownership. Buyers can pay $20,000 outright with a refundable deposit or subscribe for $499 per month. Early access includes a three-year warranty and priority 2026 delivery in the United States, with global expansion planned for 2027. – robotics news.

At CES 2026, humanoids dominated attention. Boston Dynamics revealed a production version of Electric Atlas for factory material handling. LG’s CLOiD emphasized home assistance through Vision Language Action AI. SwitchBot’s Onero H1 focused on everyday chores. These machines share a philosophy: humanoid form is not about imitation but compatibility with human environments.

Agriculture and Autonomy at Scale

Outside factories and homes, robotics is reshaping agriculture and mobility. Carbon Robotics introduced what it calls the first Large Plant Model, an AI system trained specifically on crop data to guide autonomous weeding and monitoring. By focusing on plant-level perception, the system promises reduced chemical use and higher yields.

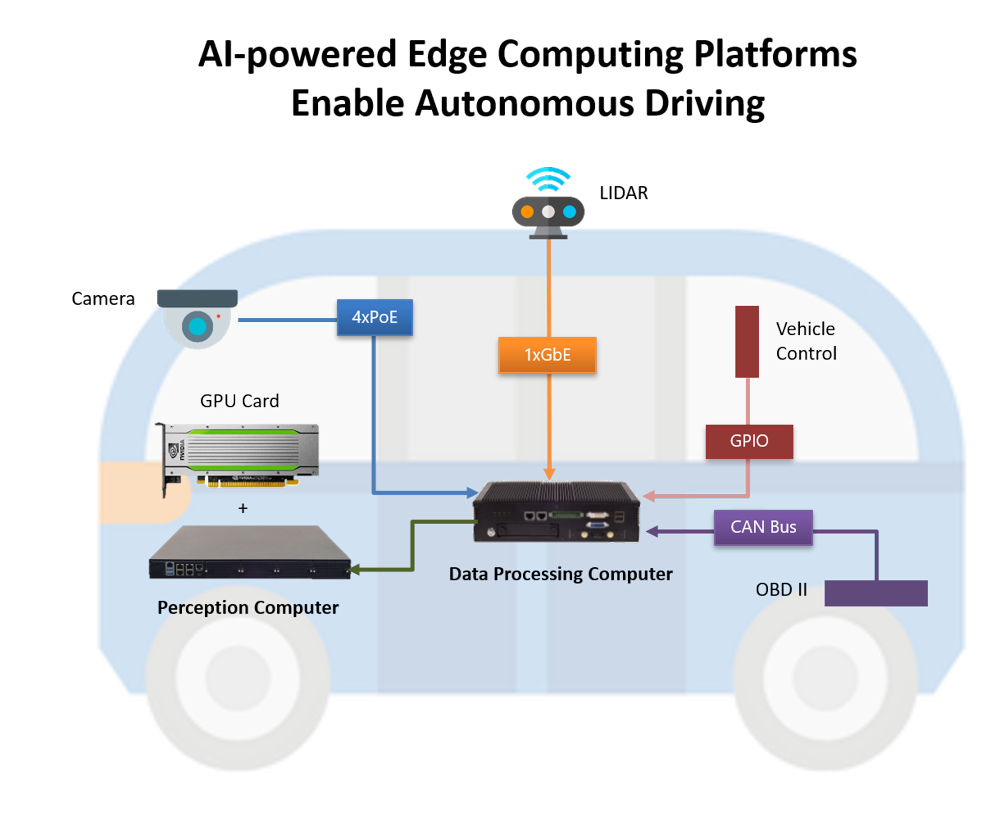

4XRobots is expanding greenhouse automation with a push into the U.S. market, targeting labor-intensive operations like harvesting and sorting. Meanwhile, autonomous driving remains a proving ground for robotic intelligence. QCraft’s new platform delivers more than 500 trillion operations per second, enabling real-time perception and planning in complex urban environments.

An agricultural technologist at a California research farm observed that “the leap isn’t autonomy alone. It’s specialization. These systems understand crops the way industrial robots understand parts.” That specialization mirrors trends in manufacturing and logistics, where domain-specific AI outperforms general models.

The convergence of robotics and agriculture raises questions about rural labor and sustainability. Yet early deployments suggest collaboration rather than replacement, with robots handling repetitive tasks while humans focus on oversight and decision-making. – robotics news.

AI Research Redefines Robotic Learning

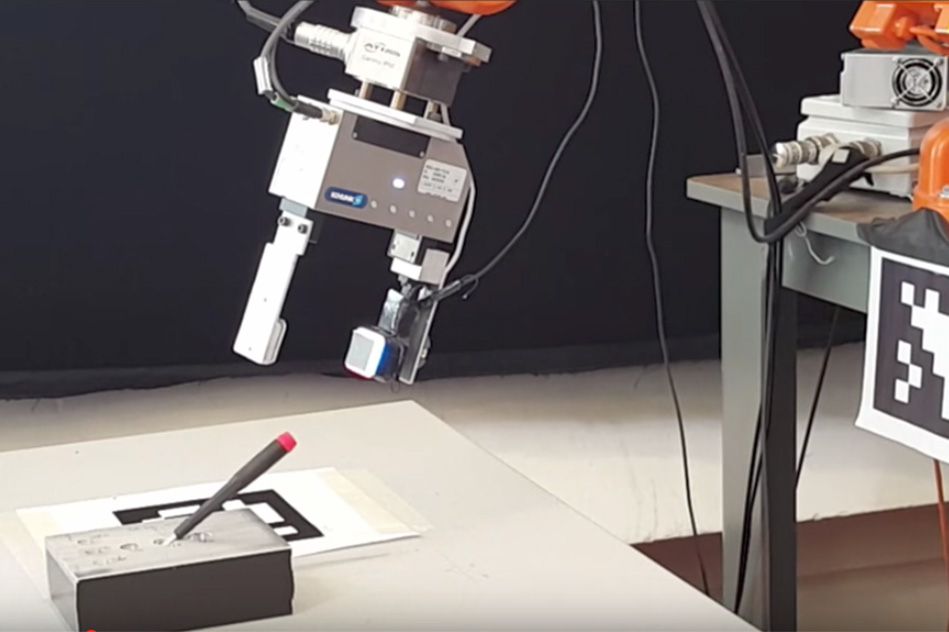

The most profound changes in robotics are happening in software. Microsoft Research introduced Rho-alpha, a model that unifies vision, language, and touch. The result is a robot that can interpret instructions, perceive objects, and adjust force dynamically, a combination long considered essential for general-purpose manipulation.

Richtech Robotics has partnered with Microsoft to deploy agentic AI systems in commercial robots, while ABB demonstrated AI-driven lab automation at SLAS 2026, automating complex workflows in pharmaceutical research.

AgiBot’s reinforcement learning system offers a glimpse of the future. Its Real-World Reinforcement Learning platform allows robots to learn new assembly tasks in minutes, adapting to variations without weeks of retraining. A manufacturing pilot with Longcheer Technology showed near-perfect task completion under real conditions.

According to a robotics professor at ETH Zurich, “we are finally seeing learning systems that survive contact with reality. That changes deployment economics completely.”

Comparative Snapshot of Leading Robotics Developments

| Segment | Company | Key Innovation | Deployment Timeline |

|---|---|---|---|

| Collaborative Robots | Omron | 30 kg payload cobots with IP65 | 2025–2026 |

| Humanoid Home Robots | 1X Technologies | NEO humanoid with remote training | 2026 |

| Industrial Humanoids | Boston Dynamics | Electric Atlas for factories | 2026 |

| AI Research | Microsoft Research | Rho-alpha multimodal model | 2025 |

| Agriculture Robotics | Carbon Robotics | Large Plant Model AI | 2025 |

Pricing and Access in the New Robotics Economy

| Product | Purchase Option | Subscription | Target User |

|---|---|---|---|

| NEO Humanoid | $20,000 | $499 per month | Households |

| TM30S Cobot | Custom quote | N/A | Manufacturing |

| Greenhouse Robots | Lease models | Varies | Agriculture |

| Lab Automation | Enterprise | Service contracts | Research labs |

Ethical and Social Friction Points

As robots enter shared spaces, questions of trust and safety intensify. Tendon-driven designs and force-torque sensors aim to reduce injury risk, but public acceptance depends on transparency. One labor economist warned that “the risk isn’t mass unemployment tomorrow. It’s uneven adoption that leaves smaller firms behind.”

Regulators are beginning to respond. Safety standards for collaborative robots are evolving, and data governance around AI-trained machines remains unresolved. The balance between innovation and oversight will shape how quickly these systems become commonplace.

Takeaways

- Collaborative robots are now handling heavy industrial tasks without cages.

- Humanoid robots are transitioning from demos to consumer products.

- AI integration is the main driver of adaptability and learning speed.

- Agriculture and mobility benefit from highly specialized robotic intelligence.

- Pricing models signal a shift toward subscription and service robotics.

- Social acceptance hinges on safety, transparency, and clear human benefit.

Conclusion

The robotics news of early 2026 tells a story of maturity. These machines are no longer novelties or distant promises. They are tools shaped by real constraints and real needs, from labor shortages to household convenience. What stands out is not a single breakthrough but an ecosystem moving in concert, hardware refined by software, intelligence grounded in physical reality.

i find it striking that the most ambitious robots today emphasize collaboration rather than autonomy for its own sake. Cobots lift heavy loads so humans do not have to. Humanoids are designed around chores, not spectacle. AI systems learn from human guidance instead of replacing it outright.

This does not eliminate disruption. Work will change, and expectations will shift. Yet the prevailing direction suggests augmentation over displacement. The next decade will test whether society can guide these technologies with the same care that engineers bring to their design. If so, robotics may finally fulfill its long-promised role as a quiet partner in human progress.

FAQs

What is a collaborative robot?

A collaborative robot, or cobot, is designed to work safely alongside humans without traditional safety cages, using sensors and force limits.

Are humanoid robots really coming to homes?

Yes. Companies like 1X Technologies plan limited consumer deliveries starting in 2026, focusing on household chores and assistance.

How does AI improve robot performance?

AI allows robots to perceive, reason, and adapt to changes, reducing the need for rigid programming and extensive retraining.

Will robots replace manufacturing jobs?

Current trends emphasize collaboration. Robots handle repetitive or hazardous tasks while humans supervise and manage complexity.

What industries benefit most from recent robotics advances?

Manufacturing, agriculture, logistics, and laboratory research are seeing the fastest and most practical gains.